Description

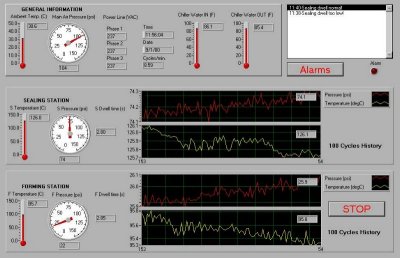

Data Acquisition System (DAS) is primarily intended for form fill and seal machines but may be used with other types of process equipment. DAS is assembled using precision commercially available and ISO 9002 compliant components supplied by National Instruments. All “vital signs” of the process are displayed and recorded automatically for each machine cycle. The process signals are recorded on the PC hard drive through the data collection card for each machine cycle. Collected data is saved in a tab-delimited file and can be imported with Microsoft Excel or other statistical software such as Statgraphics. Professional installation is performed by our engineers. For purchasing information, please contact us.

Key features

- The system precisely measures and records the cycle duration for the sealing and forming stations and the total machine cycle.

- All recorded data is time stamped.

- The system allows the administrator to set process alarm limits.

- The administrator adjustable alarm limits are:

- Forming Station Temperature

- Sealing Station Temperature

- Main Pressure, Forming Pressure, and Sealing Pressure

- All cycle Time duration

- Chiller Temperature In, Out & Differential

- Upon any process limit being exceeded the system turns on the sound/light alarm and a software alarm is triggered.

- The sound/light alarm is suppressed as soon as the operator disables it or clears the alarm list, but the data associated with the alarm will be clearly marked in the log file.

- Alarm limits and the access to alarm acknowledgment are password protected.

For each cycle the system records the following machine parameters:

| Measurement | Span | |

| Temperature | Sealing station | 32°F to 930°F |

| Forming station | 32°F to 930°F | |

| Cooling water in | 32°F to 200°F | |

| Cooling water out | 32°F to 200°F | |

| Pressure | Main airline | 0 to 150 PSI |

| Sealing station | 0 to 150 PSI | |

| Forming station | 0 to 150 PSI | |

| Voltage | 3 phase | 0 to 300 VAC |

| Time | Cycles/minute | 0 to Cycle Time |

| Forming Dwell | 0 to Cycle Time | |

| Sealing Dwell |

0 to Cycle Time |